SENIX Global Manufacturing Footprint: Faster, Smarter, Closer to Users

Why Global Manufacturing Matters to Users

In today's professional power tools industry, manufacturing locations directly impact not only product quality but also supply chain stability, delivery speed, and ultimately user experience. Facing the growing global demand for high-performance, durable lawn care equipment and portable power tools, SENIX has established an intelligent and efficient manufacturing network through its robust global production footprint, ensuring every user enjoys more reliable and efficient tool performance.

"UNSTOPPABLE POWER" is not just SENIX's brand slogan - it represents our commitment to exceptional performance through intelligent performance tracking, cutting-edge innovation, and continuous improvement in lithium-ion power systems.

How SENIX Builds a Global Production System

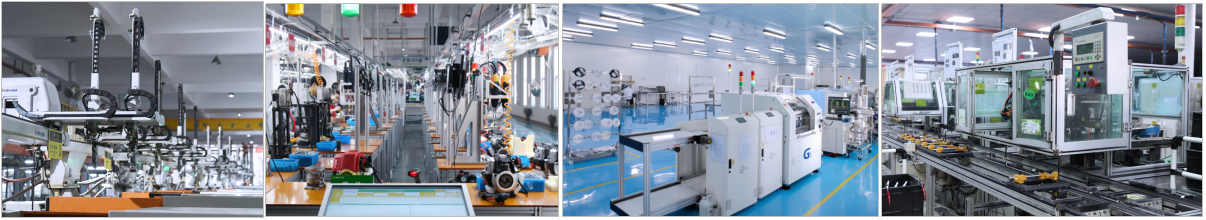

SENIX's manufacturing system covers multiple core regions including North America, Asia-Pacific, and Latin America. Through this globalized layout, we ensure seamless integration of product development, production, testing, and supply chain management for our full range of 20V/40V/60V Max cordless platforms, AC electric tools, gas-powered equipment, and intelligent tools. This strategy not only significantly shortens delivery cycles but also enables SENIX to respond quickly to regional user needs, providing more competitive product solutions.

Moreover, SENIX employs advanced production lines and rigorous quality management systems to ensure every product is manufactured to the highest standards. This system enhances product stability and guarantees excellent performance in various demanding environments, making SENIX tools trustworthy for any work scenario.

From North America to Asia-Pacific: SENIX's Global Factory Network

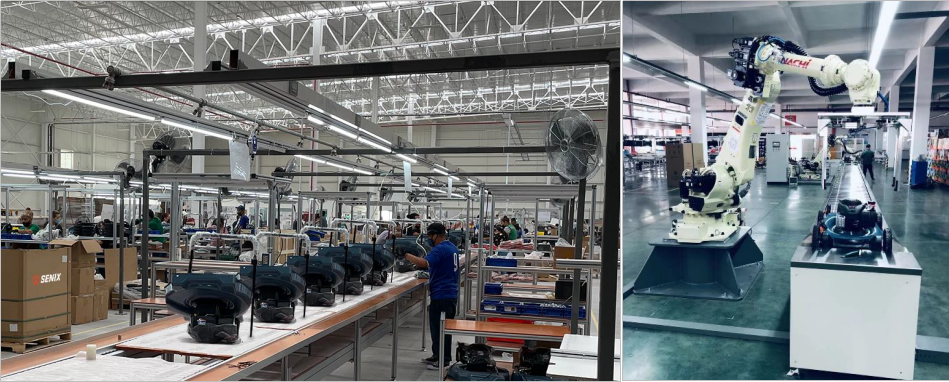

SENIX's global market expansion relies on production bases in Mexico and China, with:

Monterrey facility serving North and Central American markets

Jiaxing and Yuyao factories serving the entire Asia-Pacific region

This integrated manufacturing system not only improves production efficiency but also enables faster delivery of tools to users, reducing supply chain delays.

Simultaneously, through localized supply chain management, SENIX minimizes uncertainties caused by international transportation while reducing production and logistics costs, allowing global users to enjoy high value-for-money prosumer power tools.

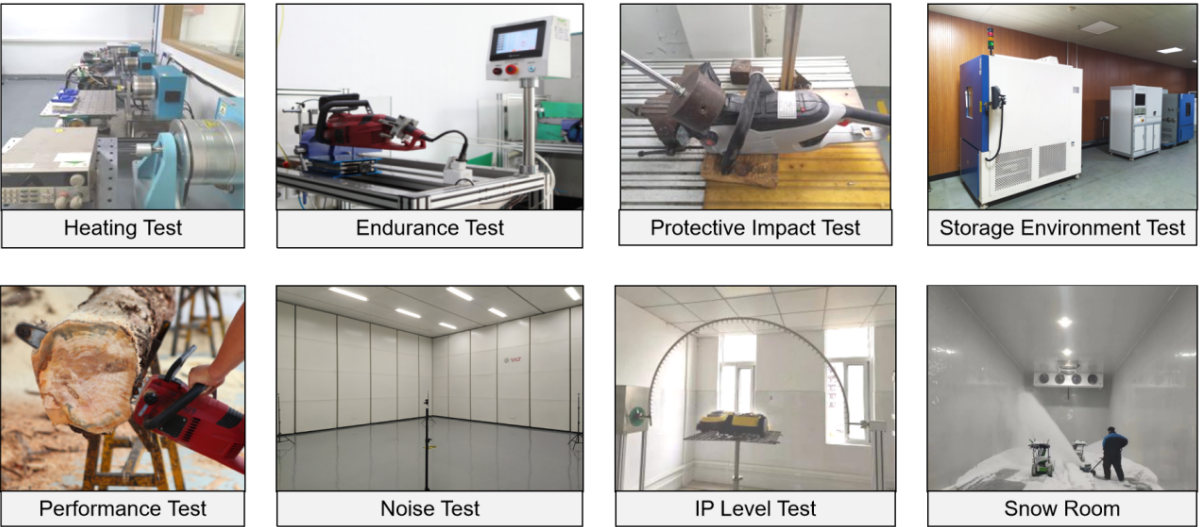

High-Standard Manufacturing: Ensuring Excellence in Every SENIX Tool

SENIX believes exceptional products require strict manufacturing standards. Our factory laboratories possess international-level testing capabilities and are authorized as witness laboratories by authoritative institutions including TÜV Rheinland, TÜV SÜD, UL, and SGS. These facilities conduct comprehensive testing including:

Additionally, SENIX has established a complete quality control system - from PPAP approval processes and product audits to 8D & CAPA customer feedback improvement mechanisms - implementing multi-layer quality assurance to ensure every product meets industrial durability standards.

Global Manufacturing Empowering User Possibilities

SENIX's global manufacturing footprint not only delivers products to users faster but also ensures our tools better meet the practical needs of different markets. Moving forward, SENIX will continue expanding manufacturing capabilities, empowering more professionals and home users through smart connected tools to make every job more efficient and effortless.

"UNSTOPPABLE POWER" is not just a slogan - it's the embodiment of SENIX's worldwide support network, consistently focused on delivering commercial-grade equipment that provides contractor-grade toughness for users worldwide.

(5.0)

(5.0)